News

-

Improved Digital Control of Spiral Pipe Welding

The world population of spiral pipe mills has increased dramatically over the past ten years and continues to grow. Part of thisexpansion is driven by the acceptance of spirally welded pipe for oil and gas transmission. This application in particular imposes stringent standards on pipe quality and therefore on manufacturing processes.

To meet this need in respect of welding technology, Oxfordshire-based Meta Vision Systems has developed an integrated, networked digital control system as the enabling technology behind what it terms the digital spiral mill. It includes industrial networking, new digital SAW (submerged arc welding) power sources, the latest digital sensors and advanced digital controls.

All can be combined into a single, integrated mill control system. As sensors and controls are accessible, it is possible to improve significantly ease of operation, fault-finding, safety and maintenance. Further benefits include additional functionality, improved ease of operation through better HMIs (human-machine interfaces), integrated data logging and remote access.

New digital welding power sources facilitate a wider range of weld procedures while at the same time being easily interconnected for ease of use. This increases efficiency in various ways while at the same time facilitating accurate parameter control and data reporting.

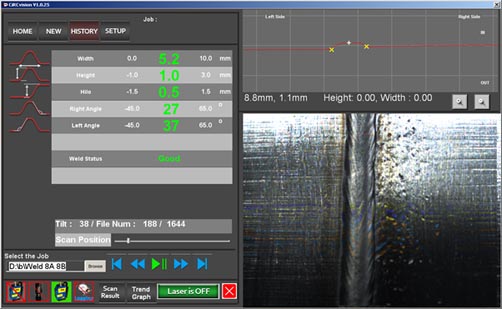

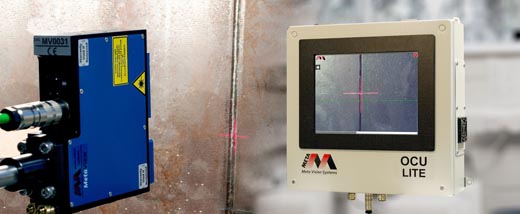

The latest laser vision sensors from Meta are being used to achieve performance gains in several areas in addition to their established use for weld seam tracking. Laser sensors can now validate weld bevels, in combination with digital signal processing for gap and mismatch control on the mill itself, and inspect weld bead profiles.

Combining mill control and weld control into a single, integrated networked system brings major advantages in terms of performance, reliability, ease of use, safety and cost. Previously, the sensing, welding and control systems were separate. For example, control of the ID and OD weld heads was often from completely independent sub systems. This meant that the respective operators had to inch, start/stop and adjust parameters locally. With an integrated system, such actions can be handled from wherever is most suitable.

The central part of the control system is a pair of networked PLCs (programmable logic controllers). One PLC controls the mill feed section, including coil loading, edge milling and main drives. The second PLC controls the forming and pay-off section, including the weld controls and laser seam tracking.

The HMI to the integrated control system is via a main control console plus a pair of intelligent consoles for the ID and OD operators and the usual local operator stations at work points distributed across the mill.

Stability of operation is a key requirement in the forming section of a spiral pipe mill. Sources of perturbations which impact negatively on stability are camber and strip width variations. One serious problem which can result from lack of stability in the forming section is inconsistent edge milling, which causes problems with forming and welding.

To monitor this, a multi-function measurement system automatically checks edge milling by measuring the bevels. This is becoming even more important with the widespread adoption of two-step spiral mill technology.

During bevel inspection, the actual shape of both sides of the strip is measured continuously by two laser sensors mounted in opposition on each side of the strip, just after edge milling but before pipe forming. If

any out-of-tolerance conditions are identified, various actions can be programmed, ranging from informing the operator to stopping the mill.

There is enormous scope for using advanced sensing and control techniques in the forming and welding section of a spiral pipe mill. Gap control refers to controlling the mill dynamically to ensure good pipe formation and an absence of defects at the ID weld station, where the weld can burn through if the gap opens up too much. Mismatch control refers to the control of the difference in height across the weld. Maximum acceptable mismatch values specified by pipe mill customers are gradually getting smaller.

One example of where mismatch control is especially important is in large diameter water pipe. Controlling the mismatch is more difficult with very large pipe diameters, for example over two metres, and yet water pipe customers are imposing stringent limits on mismatch. This has led to increased interest in automatic mismatch control to satisfy these requirements.

A laser sensor measures the gap, typically just ahead the welding point, and any deviation from target value is used to open or close the mill to maintain a constant gap. It is actually the helix angle that is being controlled, normally achieved by controlling the payoff table although controlling the angle of the feed section is an alternative method.

The sensor can be used for ID weld tracking as well as for gap measurement, although alternative approaches have also been investigated, including combined gap and mismatch control, new mechanical gap measurement sensors and positioning the laser sensor outside the pipe.

An automated mismatch control system that is separate from non-zero gap control has to be designed to cope with the fact that the measurement is being made after welding. A laser sensor makes highly accurate mismatch measurements many times per second, for example to ±0.1mm at 25Hz. The automatic control moves the actuator by exactly the correct amount to eliminate the error. Timing issues are also controlled and performance optimised based on the known positions of the actuator and sensor as well as the mill speed.

In cases where there is no gap and the edge of the incoming strip is pressing tightly against the edge of the newly formed pipe, trying to change the mismatch under these conditions can lead to unpredictable results. The pipe is less constrained than the strip and tends to move more easily, but, depending on the pressure between the two edges, relative movement may not be smooth or well controlled.

When gap and mismatch control are not independent, an alternative regime is possible. In this case, the main focus is on measuring the mismatch, since the gap is always zero, and actuation is by controlling the helix angle.

One big advantage of digital spiral mill architecture is that the welding equipment can be fully integrated with the mill control. This is particularly true in the case of the latest digital SAW power sources, such as Lincoln Electric’s PowerWave AC DC 1000SD. This power source can be relatively easily connected to a mill PLC via a DeviceNet network and also provides easy data logging via an Ethernet connection.

Having the welding equipment integrated with the overall control provides additional functionality and opportunities for system improvement, including improved operator interfaces, customer specific database storage, live parameter monitoring and warning, integrated data logging and remote internet access.

Integrating the weld controls and the laser sensors in the same system also provides an opportunity to use adaptive fill. As well as seam tracking, the laser sensor measures the actual parameters of the weld joint and can adjust the deposition rates to match.

The same type of laser sensor that is used for weld seam tracking can also monitor the weld bead. The laser sensor measures the height and

width of the bead as well as classifying the shape. Such a laser sensor can be integrated, for example, with an online ultrasonic test system, tracking the weld bead to keep the test probes centred. At the same time, the laser sensor measures and classifies the weld bead. This is becoming more important as constraints on weld beads are becoming ever tighter to improve pipe coating.

Release no: 1043(F)

-

Automated Welding Improves Safety and Productivity in Nuclear Industry

Following the introduction of its new DLS range of 3D digital laser scanners, Oxfordshire-based Meta Vision Systems has put together a VistaWeld package designed specifically to automate welding jobs in the nuclear industry. These are characterised by multiple passes of the weld torch to fill deep, narrow grooves down to 8 mm across between plates up to 300 mm thick, mainly of highly reflective stainless steel.

The company claims that this is the first time full automation has been made available for such applications, which until now have been carried out by an operator watching a camera image of the seam and using a joystick to position the weld torch manually. This is significantly slower and with up to 50 weld passes needed for the root, hot, fill and cap phases, there is risk of human error, with consequent safety and cost implications.

Factors that complicate the welding process are a need for the sensor to see from top to bottom of the groove and to illuminate the sides to ensure positional accuracy, even though the walls can be angled at one degree (i.e. are nearly vertical). Another requirement is to preheat the plate to around 300 degrees Centigrade, ensuring that there is sufficient heat to fuse the material but not enough to cause cracking and compromise structural integrity.

The VistaWeld / DLS seam searching and joint tracking system is typically used for submerged arc welding of butt, V, and U joints. It not only tracks the seam and positions the weld electrode accurately and automatically, but additionally can record position correction data for each pass to provide certification of the manufacturing process. This is an important feature for the nuclear industry, as traceability is mandatory in the event of failure.

In fully automatic, multi-pass control mode, during the first pass of each layer, the system measures the joint width at that depth and determines the number of passes required for the layer. During the last pass of each layer, the system measures the remaining depth and determines whether to continue with filling or go to capping. Advanced adaptive fill to compensate for joint area variations by controlling welding parameters directly to adjust the deposition rate at each point on the joint is available as an option.

Alternatively, in semi-automatic mode, the operator manually selects the type (root, hot, fill or cap) and position (left, right or centre) of the next pass.

Digital laser scanner is unaffected by reflections

The DLS scanning-spot laser sensor has proved to be ideal for this application. It uses a 2048 element, linear CCD (charge coupled device) and has much of the signal processing integrated inside the sensor head itself. Compressed air cooling is provided to keep the unit within its operating temperature range.

Conventional laser vision systems based on triangulation use a laser stripe projected onto the target. As constant laser power is used, it not possible to vary the intensity along the stripe to increase the light reflected from dark areas and decrease the light received from lighter areas. The camera images the complete scene including either side of the stripe, which can lead to further problems with dynamic range and unwanted reflections.

In contrast, Meta’s DLS sensor is based on a scanning spot rather than a stripe, solving the two main problems of stripe-based triangulation when dealing with shiny materials like stainless steel. First, it is easy to implement effective automatic gain control to compensate for variations in workpiece reflectivity along the length of the stripe. Second, imaging is via the CCD, which only looks at the region of interest and is not affected by reflections.

Additional benefits of the scanning technology include a programmable field of view and independence of the sensor’s depth of field from its width of field, providing high quality in both axes simultaneously. Moreover, at the touch of a button, the sensor can project the spot to measure and control standoff – the height of the end of the electrode from the weld – and to assist manual horizontal tracking.

This is normal procedure when capping. The horizontal position is obtained either from path memorisation in the case of a longitudinal welding operation, or by tracking a line scribed at the same time as the root pass weld is laid down in case of circumferential welding. Fully automatic capping with memory replay is, however, also possible.

Overall, the use of VistaWeld / DLS provides numerous benefits including higher weld speeds, better quality irrespective of operator attention level, superior interpenetration of the weld zones, reduced scrap and rework, and lower manning levels. Meta has supplied over 2,700 laser seam tracking systems worldwide.

Release no: 1039(GN)

-

Laser Seam Tracking Raises Quality and Productivity in Robotic Welding of Vehicle Exhausts

British-manufactured laser seam tracking sensors from Meta Vision Systems are increasing the efficiency of automated welding cells producing exhaust treatment products for heavy vehicles at the Nyköping factory of Swenox AB, Sweden.

European legislation on exhaust emissions is becoming increasingly stringent, which has prompted advanced on-vehicle treatment solutions to be developed by companies like Swenox to meet the requirements of lorry and bus manufacturers.

The products catalytically convert carbon monoxide, unburnt hydrocarbons and oxides of nitrogen to their harmless gaseous constituents and water vapour, and include filters to trap particulates. They are integrated into complete exhaust systems that Swenox also fabricates to customer requirements.

Design and manufacture of such system are extremely demanding, requiring gas tight joints on convoluted shapes. There are often conflicting criteria, such as a requirement to minimise weight while maintaining durability and operational reliability.

A considerable amount of arc welding is needed to join the individual components. The nature of the constituent materials results in spring back and heat distortion, making automatic welding difficult to achieve and so calling for the use of seam tracking. However, due to the large variation in reflectivity of the materials, most ordinary laser sensors struggle to detect the seams.

Oxford-based Meta Vision Systems' new SLS sensor, which forms part of its SmartLaserPilot system, has overcome the problem through its singular ability to remain unaffected by varying surface conditions and reflections from the metals being welded. It does this using real-time, automatic intensity control of the laser stripe, allowing the vision analysis software to deliver a high quality image at all times.

The Meta sensors are used in two twin-robot welding cells at Swenox, a single robot controller driving both ABB robots in each cell. The sensor head contains a megapixel camera and more computing power than a powerful laptop computer. With its weaving, seam search and reframing functions, it collects information on the position of the joint being welded and communicates it to the robot controller via an Ethernet link and switches.

Based on this data, robot motions are continuously adjusted when effecting multi-layer lap joints with tacks as well as circumferential and other welds. The welding equipment was supplied by Fronius CMT.

Glyn Powell, the engineer responsible for the robotic cells at Nyköping, commented, "Installation of the Meta SLS vision system has been a major success for Swenox.

"To be able to assemble and tack-weld components off-line and then move them into our robotic cells and weld them with consistent quality without any modification to the programs is a massive achievement.

"Our aim is to manufacture a top quality product that is the very best of its type available on the market today and without doubt the Meta laser tracking system is playing a major part in our achieving this goal."

Release no: 1042(CS)

-

New Laser Guidance System for Automated Welding in Longitudinal Pipe Mills

Meta Vision Systems (Oxford, UK and Montreal, Canada), the world's leading supplier of optical seam tracking systems for tube and pipe mills, announces a new version of its market-leading VistaWeld system aimed specifically at increasing the speed and accuracy of submerged arc welding (SAW) in longitudinal pipe mills.

Based on a review of typical longitudinal SAW mill operations involving tack and OD (Outside Diameter) welding, the new system addresses some well-known issues. In particular, the latest VistaWeld includes accurate, non-contact tracking of the true root position and built-in look-ahead compensation as standard features.

The system harnesses the power of Meta’s recently introduced Smart Laser Sensor (SLS) technology. It integrates a high resolution, high performance SLS sensor head within an updated VistaWeld architecture based on an Ethernet backbone and Meta’s new, flexible Ethernet IO board. The combination has made it feasible to include the desired features while reducing system complexity and improving ease of use.

TruRoot tracking finds the actual root of the joint for OD SAW, even though the root may be covered by the tack weld. The software uses the higher resolution and quality of the SLS sensor, together with image analysis algorithms from Meta’s well known multipass welding system, to detect the edges of the tack weld in the bottom of the joint.

From this and the overall joint profile, the true root position can be computed. Tracking the actual root derived in this way improves penetration for the OD weld itself while also improving ID/OD weld interpenetration.

OD SAW on longitudinal pipe mills typically uses a multi torch configuration with as many as five or six individual wires welding in one pool. The weld head is therefore large, taking into account the number of torches and need for flux delivery and recovery.

As a result, the laser sensor has to be positioned a relatively large distance in front of the weld area. This so-called look-ahead distance can be 250 mm or more. Depending on the shape of the pipe, tracking inaccuracies can result if simple algorithms are used.

The standard tracking feature within the new VistaWeld uses the look-ahead distance, welding speed and other information to determine the correct position for the welding head at all points along the pipe. It is particularly beneficial if the pipe forming method has given rise to geometric distortion, as is often the case.

Tests on one series of longitudinal pipes showed that, in some cases, look-ahead tracking was four times more accurate than conventional tracking, significantly enhancing production by improving weld quality and minimising defects.

For example, the superior vertical tracking accuracy maintains the correct stickout (distance from contact tip to work) over the complete length of the pipe, improving weld quality and eliminating weld defects. The improvement in horizontal axis tracking precision combines well with the TruRoot feature to give a double accuracy benefit.

According to Bob Beattie, Meta’s managing director, “We have fifteen years of experience in longitudinal pipe mills, so we were able to identify precisely how to improve our system to give their welding engineers exactly what they wanted.

"We believe that, with the new features, the new VistaWeld system is the best available on the market.”

Release no: 1041(PR)

-

New, Smart Laser Probe for Automated Welding Machines

Meta Vision Systems has launched a new laser seam tracking system that applies the company’s latest sensor technology to welding machine applications. Called Smart Laser Probe, it is manufactured at the company's Oxfordshire factory and will be demonstrated on the Meta stand at the forthcoming Fabtech exhibition in Atlanta, Georgia, 2nd - 4th November 2010.

The concept of Meta’s original laser probe was to provide laser seam tracking performance and reliability at a price roughly comparable with mechanical, tactile probe tracking. The system has proved successful in applications such as tank welding, railway wagon production, fabrication in shipyards and other automated welding operations involving simple linear, rotary or circumferential operations.

Using the latest advances in megapixel CMOS cameras, embedded electronics and high resolution displays, Meta has designed the new generation of Smart Laser Probe with significant improvements in performance, reliability and ease of use, while maintaining its competitive price.

The non-contact, seam-tracking system senses and compensates for any deviation from the nominal weld path to ensure highly accurate, automated welding, without the need for expensive fixturing or manual guidance.

Meta's SLS (smart laser sensor) technology incorporates the image processing hardware and software inside the sensor head. This greatly simplifies the architecture of the system, which uses an Ethernet backbone to communicate between the sensor head, colour touch screen display and integrated multi-function I/O board. Advanced anti reflection techniques have been incorporated in both the hardware and software, so system performance with more reflective metals such as aluminium and stainless steel is substantially improved.

Even though the electronics for image processing is now in the sensor head rather than a separate controller, as previously, a high sampling rate of 30 full frames per second at megapixel camera resolution underpins fast welding speeds and better accuracy. Additionally, partial frames can be analysed at substantially higher rates.

A further advantage of the new design is that it can tolerate a wide range of ambient temperatures from -40 °C to +55°C. The initial requirements for extended temperature operation came from applications in cross country pipelines and apply equally well to some extreme factory environments.

Ease of use has been improved by the inclusion of a controller with a colour touch screen instead of a simple monochrome video monitor. The touch screen is used for monitoring welding performance at a glance and for diagnosing any maintenance issues during operation. Multifunction I/O within the cabinet allows easy interface to a wide range of equipment.

The operator pendant has been completely redesigned to be more robust and informative. It includes multi-colour LEDs to give the operator status feedback directly from the pendant itself.

-

Meta starts KTP project on Weld Inspection with Oxford Brookes University

Meta is pleased to announce that it has partnered with Oxford Brookes University to start a new R&D project on 3D weld inspection. The two year project will be run under the UK government's Knowledge Transfer Partnership (KTP) scheme which aims to encourage links between universities and companies.

Jonathan Moore, Meta's Technical Director, commented "We are very pleased to be developing our relationship with Brookes in this way and look forward to a highly successful project in a key area for us. We have seen a rapid increase in interest in automated weld inspection over the last few years, so we felt that the time was right to build on our existing expertise by working together with the academic community."

Further details can be found at: http://www.brookes.ac.uk/business-and-employers/knowledge-transfer-partnerships/ktp-case-studies/sensing-a-good-weld--new-applications-in-computer-vision-2015/

-

New Digital Laser Scanner Speeds Welding of Wind Towers

New Digital Laser Scanner Speeds Welding of Wind Towers

-

Meta launches digital remote control system for submerged arc welding

META launches digital remote

control system for arc welding

Meta Vision Systems (Oxford, UK and Montreal, Canada) has launched a new, all-digital version of its patented MetaView system. It combines a laser-camera sensor head with a video monitor to allow a machine operator to control from a remote location both the horizontal and vertical positions of a SAW (submerged arc welding) head.

The digital version uses a colour touchscreen as the video monitor. Combined with a new, high resolution digital colour camera in the sensor head, it provides much improved image quality and noise immunity, together with many new features.

Bob Beattie, Meta’s MD, commented, “As an entry-level product, our MetaView system provides a user-friendly way of getting machine operators away from the welding head. At the same time, it actually improves their control over the position of the head in the joint, leading to better weld quality.

“Just as improved health and safety concerns rightly discourage operators from working at heights, so there is an analogous need for a system to allow welding machine operators to work remotely from a safe distance.”

In addition to providing a better, less noisy image, the digital MetaView’s functionality includes digital zoom, pan and tilt, enabling the operator to optimise the image to his or her preference. New also is the ability to add a second camera to provide an overview of the weld head to complement the detailed positional view provided by the MetaView sensor.

Release no: 1051(PR) (download PDF)

-

META to launch new robot welding sensor at Fabtech

Meta Vision Systems (Oxford UK and Montreal Canada) announces the launch of a new laser sensor at the forthcoming Fabtech show in Atlanta, Georgia, to be held from 11th to 13th November 2014.

Known as SLS ARC, the new model is an extension of Meta’s successful range of Smart Laser Sensors, optimised for robotic arc welding applications. It is suitable for seam finding and real-time weld seam tracking in all of the usual welding processes, including high current GMAW and FCAW.

Steve Thacker, Meta’s General Manager, commented “Meta was spun out of Oxford University in 1984 to commercialise a research project that developed a laser vision sensor for use in robotic MIG welding in the automotive industry. The SLS ARC represents the latest development in a thirty-year sequence which started with that first Meta sensor.

“The automotive sector represents an important and still growing part of our business, and one where we have had very good recent success. We felt it was timely to build on that success with a new sensor fine-tuned for aggressive robot welding applications. The ARC is just one part of an overall product development plan aimed at extending the state of the art in robot welding.”

By using some of the inherent advantages of SLS technology, including fully automatic image quality optimisation, combined with new sensor optics and a mechanical design matched to the requirements of robot arc welding, the SLS ARC provides a high performance laser sensor in a rugged package as demanded by the automotive industry.

The SLS sensor series is the cornerstone of Meta’s Smart Laser Pilot (SLPi) system, which exploits direct Ethernet connection from the sensor head directly to the robot controller to give excellent seam finding and real-time tracking performance with a simple system hardware architecture.

Jonathan Moore, Meta’s Technical Director, explained “The SLS family has been successful, not only because it was the first welding sensor to include the image processing inside the sensor head, but also because it encompassed several new developments and ways of improving particular features, all of which resulted in better performance while achieving a very competitive price. The ARC takes that approach one step further by using the technology features in the best possible combination for robot arc welding.”

Release no: 1050(PR) (download PDF)

Pages

- « first

- ‹ previous

- 1

- 2

- 3