Fabtech Summary

The weather for this year's Fabtech in Atlanta started off as very mild but ended with a cold front sweeping through the city. Fortunately, the same could not be said of the show itself which was positive throughout.

Meta's booth had a number of live systems operating continuously during the show. Perhaps the most impressive was the robot demo, in which Meta's new SLS ARC sensor, mounted on a Fanuc robot, performed on several different weld joint types. One showed how adaptive welding on a curved part would work. Each pass over the joint started out without a weave, but as the joint opened up, the sensor reported the increasing gap to the robot controller which generated a weave pattern of increasing amplitude, while at the same time the sensor and robot followed the curved path. Many of the younger visitors told us that they found this demo to be really "cool". The older guys said it seemed to work ok. You can download our Fabtech 2014 newsletter here.

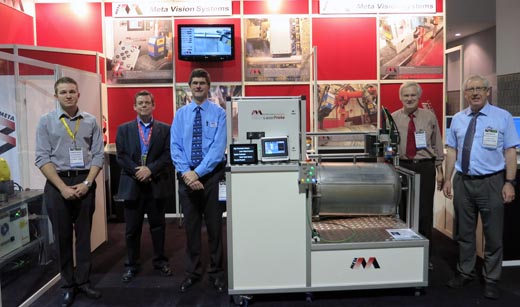

We also showed a tank welding simulation in which Meta's Smart Laser Probe system tracked a circumferential joint. The joint profile was a butt with very little gap or hilo across the joint and specialists in the tank industry seemed to appreciate the relaibility of the system. The tank demo is shown below with the Meta team at the event.

Meta is celebrating its 30th anniversary this year and so it was also good to catch up with many old friends in the business. It's amazing how many of us are still doing the same kind of thing after twenty five or more years. There is no doubt that the welding industry is a stable one by some modern standards.

Overall, we felt that the show was a good one with upward signs for the industry in North America. Now, we have a lot of leads to follow up...